7 Game-Changing Hidden Handles for a Sleek Cabinet Look

Nowadays, customized furniture trends lean towards simplicity and integration, leading many to recommend avoiding surface-mounted hardware handles. Exposed hardware handles can pose risks such as hitting people or hooking clothes. Additionally, they can disrupt the seamless look of customized furniture door panels. Therefore, eliminating exposed hardware handles is a wise choice for maintaining aesthetic integrity.

But how do you open your cabinet doors without exposed hardware handles? The solution lies in hidden handles. By integrating hidden handles, you can maintain the clean, streamlined look of your furniture while ensuring functionality. Here are 7 hidden options that guarantee a flawless appearance while offering easy access. These hidden selections are not only practical but also add a stunning effect to your cabinetry, proving that functionality and aesthetics can go hand in hand.

Unusual Diagonal Cut Handle

As the name suggests, a diagonal cut handle involves making a precise diagonal cut at the edge of the cabinet door. This creates a gap between adjacent doors, allowing fingers to easily grasp the cut surface for opening and closing.

Though this method appears simple and avoids adding extra hardware, it demands meticulous attention to detail, especially in edge banding. Poor edge banding can result in uneven surfaces and diminish the aesthetic appeal. Additionally, this design leaves small gaps between the door and cabinet, accommodating fingers and adding a subtle, intriguing sense of texture.

Slant cut handles are typically used on double-faced door panels, making them suitable for a variety of applications including cabinet doors, drawers, hanging cabinets, and floor cabinets. This innovative approach not only enhances functionality but also contributes to a sleek and modern design, seamlessly blending with contemporary furniture trends.

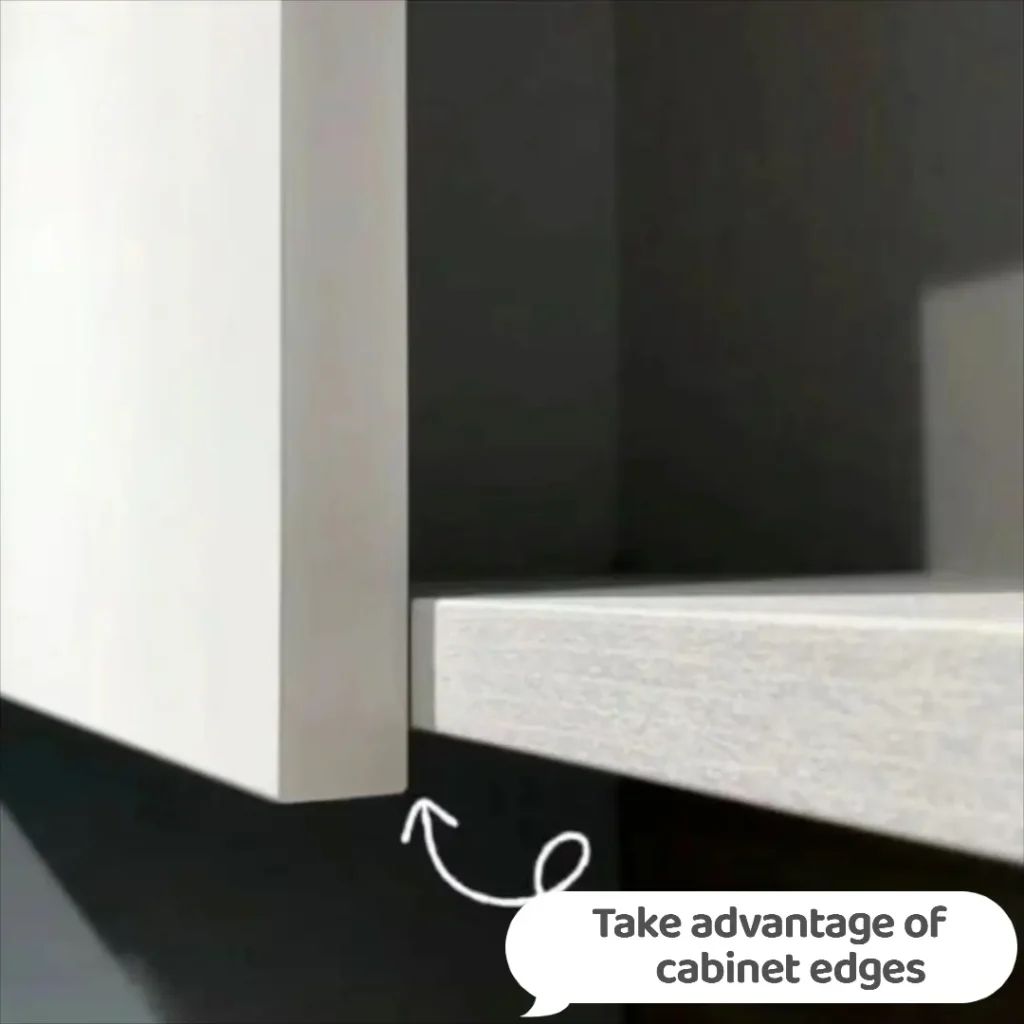

Extension of Taller Door Panels

To put it simply, extending the door panel involves making it about 2 centimeters longer, allowing the protruding part of the door panel to serve as a handle for opening and closing the cabinet. This design is particularly effective for hanging cabinets, as the door panel can extend downward to cover the bottom plate, creating a seamless and aesthetically pleasing appearance.

This method has several advantages. It offers a clean and minimalist look, avoiding the need for visible handles, and the construction difficulty is relatively low. It effectively addresses the challenge of opening and closing cabinet doors without traditional handles, enhancing the overall sleek design of your cabinetry.

However, there are limitations. This method is not suitable for cabinets with very tall doors. If applied to floor cabinets, extending the door panel upwards can result in the door panel being higher than the countertop, which can be impractical and may lead to the accumulation of dirt and grime. Additionally, the extended part might make it difficult to use the countertop effectively.

Despite these limitations, the extension method remains a popular choice for hanging cabinets, offering a simple yet elegant solution for modern, handle-less cabinet designs.

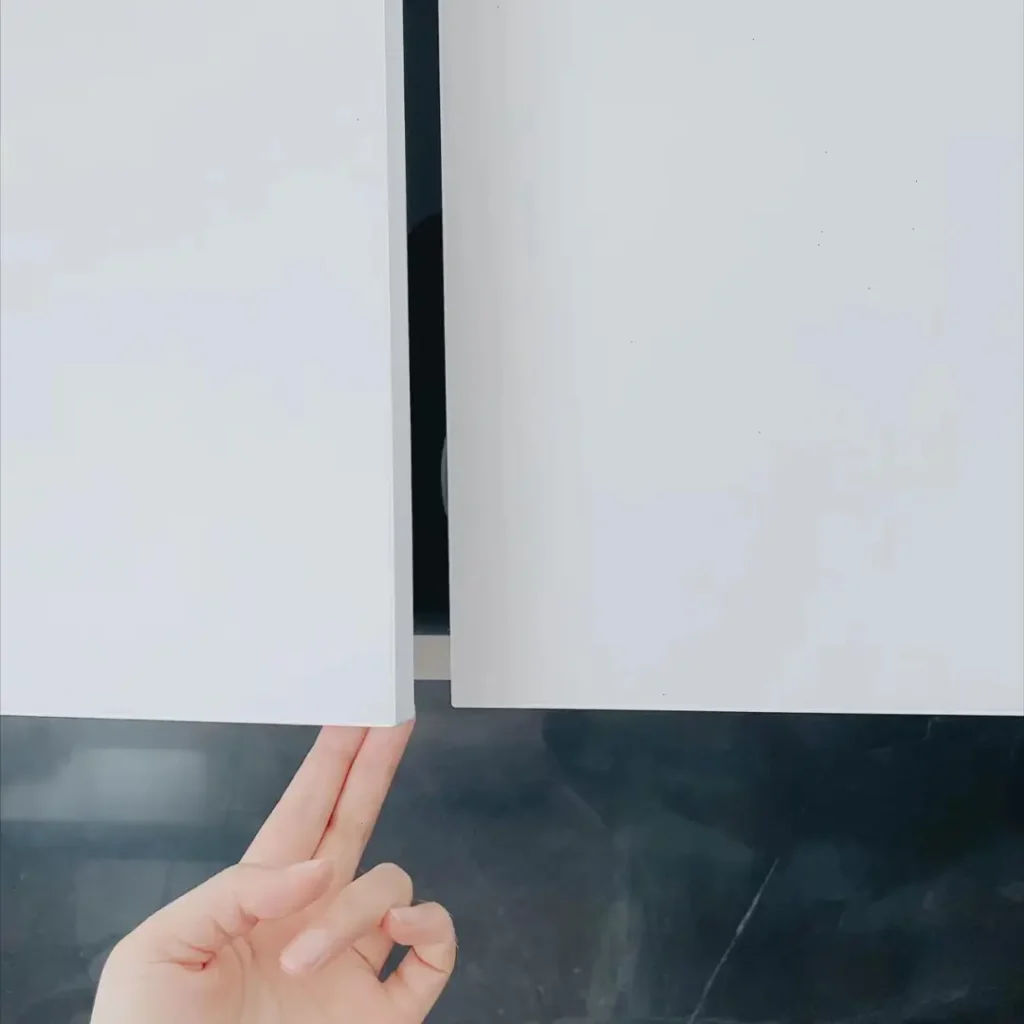

Leave Gaps in Cabinet Doors with Shorter Stature

The concept of leaving gaps in cabinet doors is the opposite of extending door panels. This method involves shortening the door panel to create gaps between the upper and lower door panels or between adjacent left and right panels. These gaps allow fingers to penetrate and use the friction between fingers and the side of the cabinet door to open it.

This approach is similar to the diagonal cut original method, requiring gaps between cabinet doors to facilitate finger access. However, unlike the diagonal cut, which provides a better grip for applying force, this method relies solely on friction, making it less effective for larger or heavier doors.

Leaving seams on cabinet doors is essentially a simplified version of the diagonal cutting handle, significantly reducing the difficulty of the manufacturing process. While it may not offer as smooth or effective an opening and closing experience as the diagonal cut handle, it is still a practical solution for achieving a special design.

This method can also be combined with internal grooves on the cabinet body, enhancing the comfort of opening and closing the cabinet door. However, it’s important to note that internal grooves can accumulate dust, increasing cleaning and maintenance efforts. Despite this, the approach remains a viable option for those seeking a minimalist, handle-less look while balancing ease of use and construction simplicity.

Grafted G-Shaped Handles

G-shaped handles represent a modern evolution of traditional surface-mounted options. Instead of being attached to the front of the door panel, these handles are installed on the side, becoming an integral part of the door itself. This flattened treatment allows the design to blend more seamlessly with the cabinet.

G-shaped selections are available in various colors, typically chosen to match the door panel and minimize their visual presence. However, achieving a perfect color match can be challenging, and slight variations may still be noticeable.

The appeal of G-shaped options largely depends on personal preference. Some find that these additions add a high-end touch to the cabinet, serving as a stylish embellishment. Others, however, feel that even side-mounted elements can disrupt the overall integrity of the design and do not fully solve the issue of visible hardware.

Ultimately, the decision to use G-shaped handles comes down to whether you value their subtle sophistication or prefer a completely handle-less look. For those who appreciate the added detail, G-shaped selections offer a refined and functional solution that maintains a degree of minimalist elegance. They provide a sleek and modern alternative to traditional hardware, enhancing the aesthetic of contemporary cabinetry without compromising on functionality.

Finely Crafted Milling Groove Handle

A finely crafted milling groove handle offers an elegant solution by integrating the handle directly into the cabinet door itself. Unlike G-shaped methods that can appear abrupt, milling groove handles maintain the overall integrity and seamless appearance of the cabinet door.

This design involves creating a groove in the door panel, resulting in a small, precise opening that avoids leaving excessive gaps. The slotting can be combined with decorative shapes, enhancing the visual appeal and achieving a sophisticated look that surpasses the appearance of both gap-based designs and G-shaped handles.

However, milling groove handles come with certain limitations. They are best suited for painted doors and molded doors, making them challenging to implement on other types of door panels, such as double-faced doors. Despite their aesthetic superiority, the limited applicability of milling groove handles is a notable drawback.

Overall, the milling groove handle offers a refined and integrated look, providing a high-end finish to your cabinetry. While it may not be suitable for every door type, it is an excellent choice for those seeking a minimalist yet decorative solution.

Embedded Profiles Hidden Inside Cabinet Doors

Embedded profiles offer a clever alternative to traditional designs, resembling the concepts of leaving seams or diagonal cut handles but simplifying the execution with an embedded profile. This design involves installing a profile within the edge of the cabinet door, allowing for a grip without the need for visible hardware.

From an aesthetic standpoint, embedded profiles achieve a similar seamless appearance to the diagonal cut handles and door gap designs. However, they excel in terms of convenience and construction ease. Unlike the gap method, embedded profiles provide a more secure and comfortable grip, making them easier to use. Additionally, they reduce the construction complexity associated with diagonal cuts, offering a more straightforward installation process.

Embedded profiles effectively avoid the drawbacks of the previous methods, combining the best features of each while maintaining a clean and minimalist look. This design is particularly advantageous for those seeking a handle-less appearance without compromising on functionality or ease of installation. By integrating the profile within the cabinet door, this method ensures a sleek and sophisticated finish that enhances both the aesthetic and practical aspects of your cabinetry.

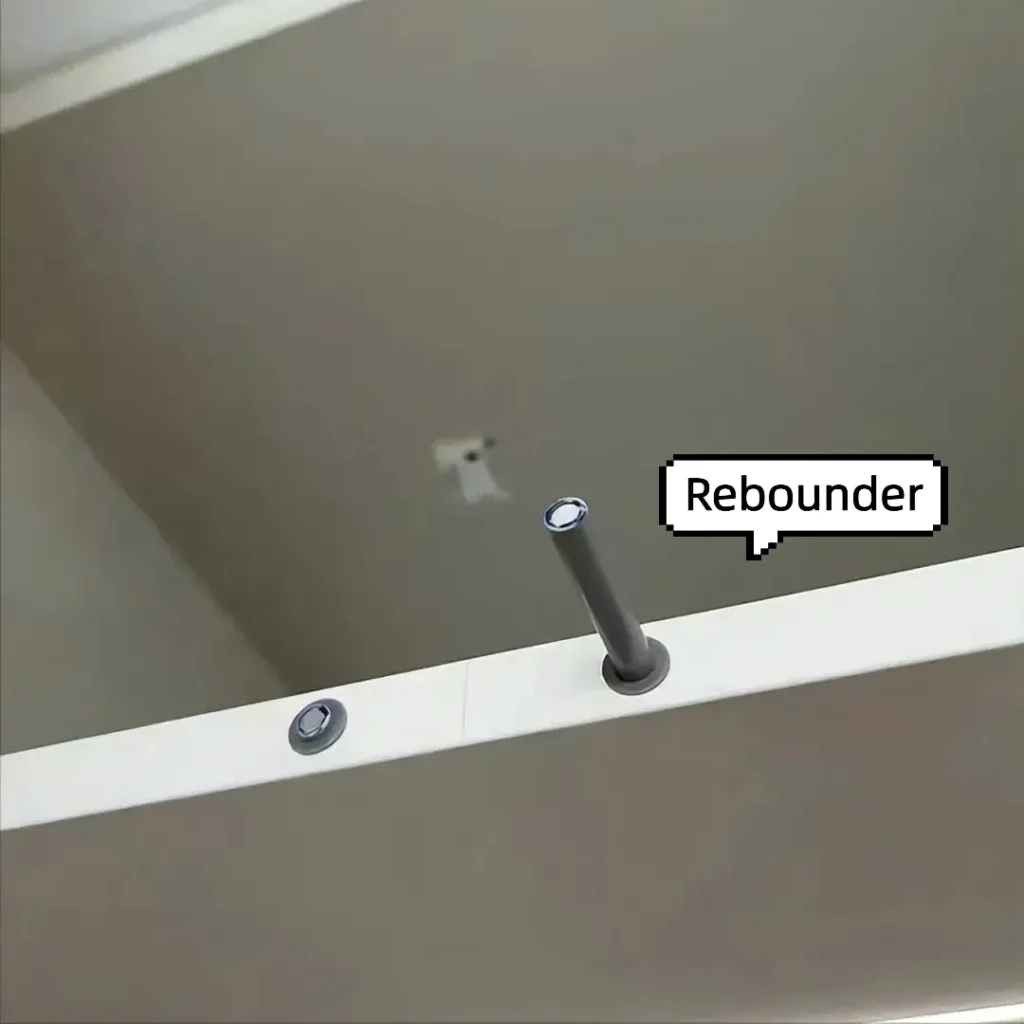

A Hilarious Rebound Device

A rebound device offers a unique and innovative solution for handle-less cabinets. This mechanism allows you to open the cabinet door by pressing on it to pop it open and pressing again to close it. This design eliminates the need for excessive processing or gaps, maintaining the simplicity and integrity of the cabinet door.

While the rebound device sounds ideal, it hasn’t been widely adopted due to reliability issues. Despite its aesthetic advantages, the device is prone to failure, especially with prolonged use. Imagine the frustration of pressing to open a cabinet door only to have it remain stubbornly closed, or pressing multiple times without any response.

If you choose to use a rebound device, it is advisable to opt for a reputable brand known for better quality. However, even top-quality rebound devices cannot guarantee flawless operation every time. The risk of malfunction means you might occasionally face the annoyance of a non-responsive cabinet door.

In summary, while rebound devices can achieve a sleek and handle-less look, their practical drawbacks might outweigh their aesthetic benefits. It’s essential to weigh the convenience of use and potential for failure when considering this option for your cabinets.